Learn general information on our production and scope of services.

Clearly, the tasks are differently, so there is no solution from the "rod".

So, talk to us, what can be done.

Sinus Magnettechnik GmbH provides you a number of services around the use of permanent magnets.

The main focus is the production of magnetizers and fixtures for magnetisation of permanent magnets and the integration in automated production processes.

Connected to this are services like magnetization of small batches of permanent magnets including testing and documentation.

We do in our facility also magnetization of small batches of permanent magnets.

If you have no capacity for limited-lot production or test magnetization we can do this in most cases for you.

We have magnetizers in different power classes and a selection of fixtures on store, so we can solve your requirements in a short time.

If we don't have a fixture on store that fits your requirements we are able to develop and produce a fixture according your wishes. This fixture can be stored in our house for future orders or it will be sent to you for use with your magnetizers.

During magnetization we do a hysteresis with sample parts. The achieved flux with be tested using random samples. If requested each part will be tested.

The most simple magnetizers are permanent magnets or coils using constant current.

The most simple magnetizers are permanent magnets or coils using constant current.

Due to low field strength they are suitable only for low coercive magnetic materials like AlNiCo or ferrite. The advantages of these constructions are the low costs and high rate of production.

The magnetization of modern magnet material with high coercive field strength requires much higher current than those are reachable with constant current applications.

This is the application area for impulse magnetizers.

Impulse magnetizers consist mainly in a capacitor bank, one or more SCR's and a coil. For magnetization the capacitor bank is discharges by the SCRs thru the coil and produces there the desired field strength.

Due to the modular assembly of our magnetizers we are able to adapt it optimal to the customers' requirements. So the maximum voltage can be adjusted to the max necessary energy, the charging unit according the rate of production or the pulse shape (sine, e-pulse or demag) to the assembly of the magnets or desired operating conditions and interfaces can be selected to the integration of production. In this way you get a devices that suits best your requirements.

For quality control our devices can be equipped with current supervisory.

The operating safety of the magnetizer is assured by various active and passive safety functions.

According the maximum energy of the magnetizer our devices are manufactured in different voltage levels. This is necessary, because with increasing capacity the pulse length increases too and due to this a higher rate of the energy heats up the fixture. That also means the rate of production decreases to avoid overheating of the fixtures. To avoid this we use for magnetizers with higher energy higher voltages.

To keep the costs of our devices as low as possible we deploy different voltage levels like 2000V, 3000V and 4000V.

Independent of the voltage levels the magnetization voltage is selectable in 1V steps.

For magnetization of permanent magnets there are different pulse shapes useable.

Each of these offers advantages and disadvantages, so it is necessary to select it to the application area. If the magnetizer is used for different jobs it is possible to integrate more than one pulse shape in a device. The selection of the pulse shapes then is done electronically by selecting it at the control unit.

Sine

Using this shape the magnetization is done by a current that follows a half sine wave.

The advantages of the sine shape underlie the short length:

e-pulse

The current raises here like a quarter sine wave and devreases exponentioal.

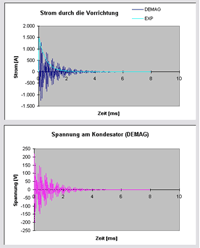

Demag

The current follows a damped sine wave. This pulse shape is used for demagnetization of permanent magnets.

For the best possible integration in automated production processes our magnetizer are equiped serially with a plc interface.

Using this interface it is possible to initiate each step for magnetizing and read out the current operating state. Due to this operating independent of operating staff is possible.

For special purposes it is possible to integrate a RS232-interface. Using this interface all magnetizing parameters can be programmed and read out remotely.

In combination with the magnetizer inside the fixtures high impuls currents produce strong magnetic fields for magnetizing the work piece.

The shape and size of the fixture is mainly defined by the work piece and the alignment of poles.

Due to the from part to part different requirements each of our fixtures will be designed newly to their application and optimized to saturation and pole gap.

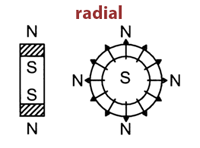

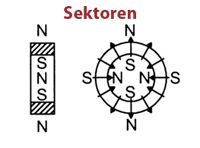

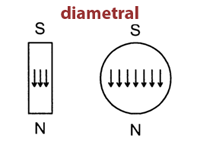

Generally there can be differentiated 4 kindes of alignment of poles:

|

|

| Radial: the field lines run along the radius of the work piece | Sectors: using more than 2 poles the field lines run in different areas of the work piece in different directions |

|

|

| Axial: the field lines run along the axis of the workpiece | Diametral: the field lines run perpendicularly to the axis of the work piece |

To reach a desired economic production rate it is often necessary to cool the fixtures to increase the lifetime.

As coolant we use air that is blown by a fan inside the fixture.

According the requirements of the production the magnetization of the work pieces is done at the surface of the fixture ( e.g. speaker that is transported by a conveyer across the fixture) or inside the fixture. This can be assisted by a pneumatic system that can be integrated by us.

Information about our products and services can be found here.

Information about our products and services can be found here.

| phone | +49-395-4691899 |

| 24 h reachable! | |

| info@sinus-magnettechnik.de |